LiftPoint LTX-18/22/30

18,000, 22,000 & 30,000 LB. FORKTRUCK/MATERIAL HANDLING SERVICE LIFT

SAFE LIFTING IN 60 SECONDS! The only lift designed to service forklifts, pallet jacks, reach trucks, order pickers & more

• Speeds Repairs & Boosts Fleet Reliability

• Improves “PM” Compliance

• Reduces Parts Expenses

• Reduces Injuries & Improves Ergonomics

• Reduces Workman’s Comp Exposure

Overview

HEAVY DUTY LIFTS FOR HEAVY DUTY SERVICE

LIFTPOINT DESIGN

LiftPoint columns are constructed of 3⁄4” thick forklift masts, for a lifetime of trouble-free service and reliability.

-

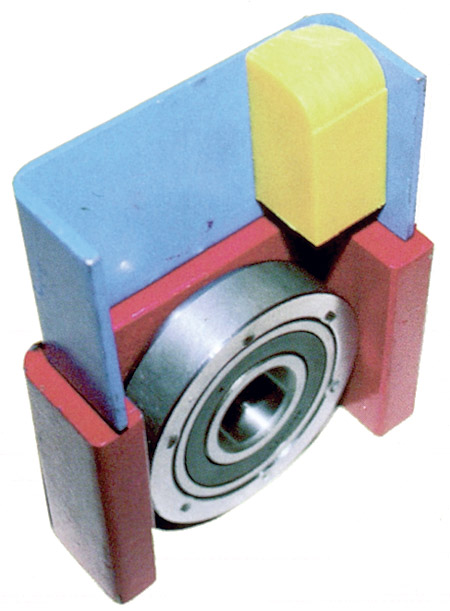

Each LiftPoint carriage rolls on 8 double-sealed, self-lubricating, steel ball bearing rollers.

-

Two 4” heavy duty cylinders (one in each post) make for a safe and stable lift.

-

Low profile (1.5”) three stage swing arms fit under most material handling equipment (lower profile adapters available).

-

Adjustable three stage arms ensure compatibility with fleets of various model types, lengths and widths.

-

Easily adjustable overhead stainless steel hydraulic lines can be set at any height (or routed in floor) to accommodate even the tallest masts.

LIFTPOINT’S PATENTED INDUSTRY LEADING SAFETY SYSTEMS

Patented, infinite-position, internal hydraulic safeties backed by external pressure compensated flow controls and velocity fuse valving.

-

LiftPoint lifts feature all position mechanical safety locks in both columns, starting at the ground, to full lifting height.

-

Swing arm restraints automatically engage upon lifting and automatically disengage when the material handling equipment has been fully lowered.

-

Electric safeties prohibit overloading of system.

-

The best, and most inclusive warranty in the business; 25 years structural, 10 year mechanical, plus limited lifetime cylinder seal warranty.

LIFT OPERATION

-

Hydraulic fluid is pumped between the two cylinders through the overhead (or optional in-floor) stainless steel hydraulic lines.

-

Patented hydraulic synchronization system ensures even lifting and eliminates the need for restrictive height overhead covers, cables, pulleys, equalizer chains or obstructive floor plates.

-

To raise the carriages, the LTX Series uses a true piston and ram system, direct drive lifting rods and high quality U.S. power systems for smooth, stable, reliable lifting.

-

LiftPoint’s welded steel carriages roll on eight double sealed, self-lubricating, steel ball bearing rollers, and incorporates a thrust load bearing design to dissipate the thrust from heavy counterbalanced forklifts.

-

LiftPoint bearings last longer, with less friction and wear than competitive lifts using plastic slide blocks which need constant greasing and maintenance.

Specifications

| Model: | LTX-18/LTX-22 |

| Capacity: | 18,000/22,000 lbs. |

| Motor Rating: | 4 HP/208-230V, Single-phase (3ø optional) |

| Synchronization: | Hydraulic fluid displacement using no chains, cables, or overhead obstructions |

| Arm Pad Height: | 1 1⁄4″ min. |

| Lifting Height: | 6′ under arm |

| Overall Width (adjustable): | 12′ 7 1⁄2″ |

| Weight: | 3,200 – 3,800 lbs. |

| Concrete Floor Requirements: | Wide Base: 5 1⁄2″ of 4,000 psi concrete Standard Base: 6 1⁄2″ of 4,000 psi concrete |

| Standard Base: | 6 1⁄2″ of 4,000 psi concrete |

| Anchoring System (included): | (16) 3⁄4″x6″ bolts |

| Mechanical Safety Locks: | Automatic; multi-position starting @ 5″ off the floor |

| Hydraulic Safety Systems: | Automatic; infinite-position |

| Swing Arm Restraints: | Automatic upon ascent |

| Cylinders: | 2 (1 per column) |

| Drive System: | Direct drive (using no cables or chains) |

| Lifting Speed: | 60 seconds (faster with lighter load) |

| Thrust & Guide Bearings: | (16) 4″ diameter, (8 per carriage) double sealed, self-lubricating ball bearing rollers |

| Floor Access Between Posts: | Clear and unobstructed |

| Warranty: | 25 years structural |

- Overview

- Features & Images

- Options & Accessories

- Specifications

- Support

-

HEAVY DUTY LIFTS FOR HEAVY DUTY SERVICE

LIFTPOINT DESIGN

LiftPoint columns are constructed of 3⁄4” thick forklift masts, for a lifetime of trouble-free service and reliability.

-

Each LiftPoint carriage rolls on 8 double-sealed, self-lubricating, steel ball bearing rollers.

-

Two 4” heavy duty cylinders (one in each post) make for a safe and stable lift.

-

Low profile (1.5”) three stage swing arms fit under most material handling equipment (lower profile adapters available).

-

Adjustable three stage arms ensure compatibility with fleets of various model types, lengths and widths.

-

Easily adjustable overhead stainless steel hydraulic lines can be set at any height (or routed in floor) to accommodate even the tallest masts.

LIFTPOINT’S PATENTED INDUSTRY LEADING SAFETY SYSTEMS

Patented, infinite-position, internal hydraulic safeties backed by external pressure compensated flow controls and velocity fuse valving.

-

LiftPoint lifts feature all position mechanical safety locks in both columns, starting at the ground, to full lifting height.

-

Swing arm restraints automatically engage upon lifting and automatically disengage when the material handling equipment has been fully lowered.

-

Electric safeties prohibit overloading of system.

-

The best, and most inclusive warranty in the business; 25 years structural, 10 year mechanical, plus limited lifetime cylinder seal warranty.

LIFT OPERATION

-

Hydraulic fluid is pumped between the two cylinders through the overhead (or optional in-floor) stainless steel hydraulic lines.

-

Patented hydraulic synchronization system ensures even lifting and eliminates the need for restrictive height overhead covers, cables, pulleys, equalizer chains or obstructive floor plates.

-

To raise the carriages, the LTX Series uses a true piston and ram system, direct drive lifting rods and high quality U.S. power systems for smooth, stable, reliable lifting.

-

LiftPoint’s welded steel carriages roll on eight double sealed, self-lubricating, steel ball bearing rollers, and incorporates a thrust load bearing design to dissipate the thrust from heavy counterbalanced forklifts.

-

LiftPoint bearings last longer, with less friction and wear than competitive lifts using plastic slide blocks which need constant greasing and maintenance.

-

Model: LTX-18/LTX-22 Capacity: 18,000/22,000 lbs. Motor Rating: 4 HP/208-230V, Single-phase (3ø optional) Synchronization: Hydraulic fluid displacement using no

chains, cables, or overhead obstructionsArm Pad Height: 1 1⁄4″ min. Lifting Height: 6′ under arm Overall Width (adjustable): 12′ 7 1⁄2″ Weight: 3,200 – 3,800 lbs. Concrete Floor Requirements: Wide Base: 5 1⁄2″ of 4,000 psi concrete

Standard Base: 6 1⁄2″ of 4,000 psi concreteStandard Base: 6 1⁄2″ of 4,000 psi concrete Anchoring System (included): (16) 3⁄4″x6″ bolts Mechanical Safety Locks: Automatic; multi-position starting @

5″ off the floorHydraulic Safety Systems: Automatic; infinite-position Swing Arm Restraints: Automatic upon ascent Cylinders: 2 (1 per column) Drive System: Direct drive (using no cables or chains) Lifting Speed: 60 seconds (faster with lighter load) Thrust & Guide Bearings: (16) 4″ diameter, (8 per carriage) double sealed, self-lubricating ball bearing rollers Floor Access Between Posts: Clear and unobstructed Warranty: 25 years structural